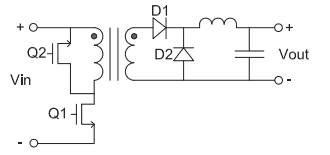

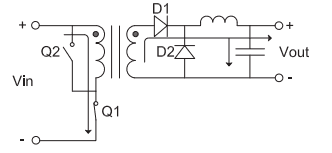

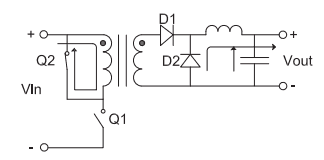

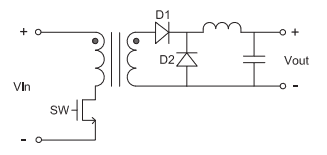

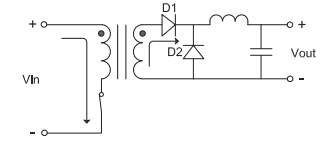

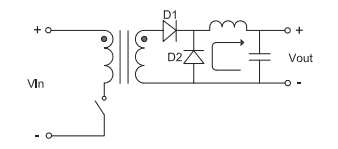

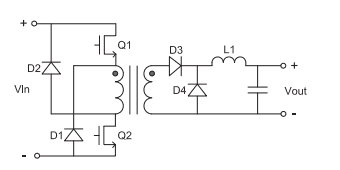

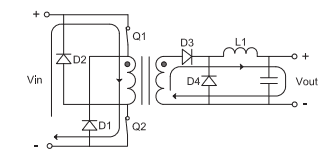

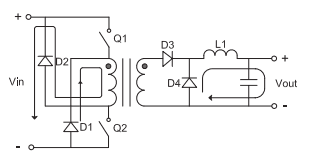

Forward converters have been popular on the market for switching-mode power suppliers. Like the flyback topology, the forward converter is best suited for an intermediate power output level of 100–200W. While its efficiency is comparable to the flyback configuration, it has the advantage over the flyback when high output currents are required. Nevertheless, the forward converter must have an extra inductor on the output side and is not suitable for high voltage outputs.

Although the general appearance of the power stage is similar to that of the flyback configuration, the mode of operation is completely different. The primary and secondary windings are in phase so that energy will be transferred to the output circuits when the transistor is “on”. The forward transformer operates with a low output resistance, and thus a filter inductor is required to limit the current flow in the output rectifier, the output capacitor, and the load.